KRAFT PAPER

In general following steps are involved in paper making process

Raw Material Preparation

Agricultural residue like wheat straw, bagasse &sarkanda are basic raw material being used for paper making. First of all dry depithing is being done through duster drum to remove dust, sand and fines followed by wet washing to further remove the attached soil and sand etc in twin turbo washers and aqua separator.

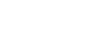

Cooking

Dedusted raw material is cooked in Spherical rotatory digesters along with Caustic & steam at desired temperature and pressure to get cooked pulp.

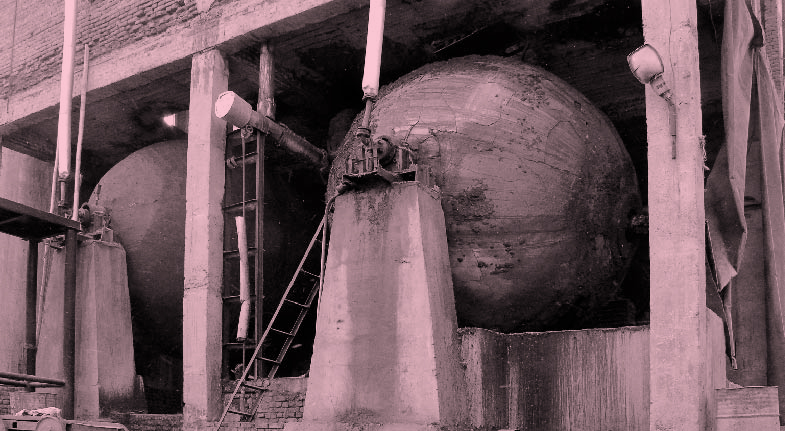

Refining, Washing

& Screening

Cooked pulp is refined, screened & washed through Brown stock washer &Delker Washer (Imported from South Africa) with hot water. Black liquor recovered from washing is send to Soda Recovery plant for further recycling and recovery of chemicals & steam. Refining is done to get better fiber bonding & to improve physical strength properties of Pulp and Paper & Burst factor is being maintained 20 Plus.

Waste Paper Street

Waste paper is collected from local market and directly slashed in Intensapulper with back water and passed through screening, centri cleaning system to remove unwanted material like dust, sand, plastic etc.

Stock Preparation

Agro Pulp and Waste paper pulp stored in different towers and mixed through on line mixer in proper ratio as per quality of paper and various chemicals like sizing, etc mixed here for better strength of paper.

-

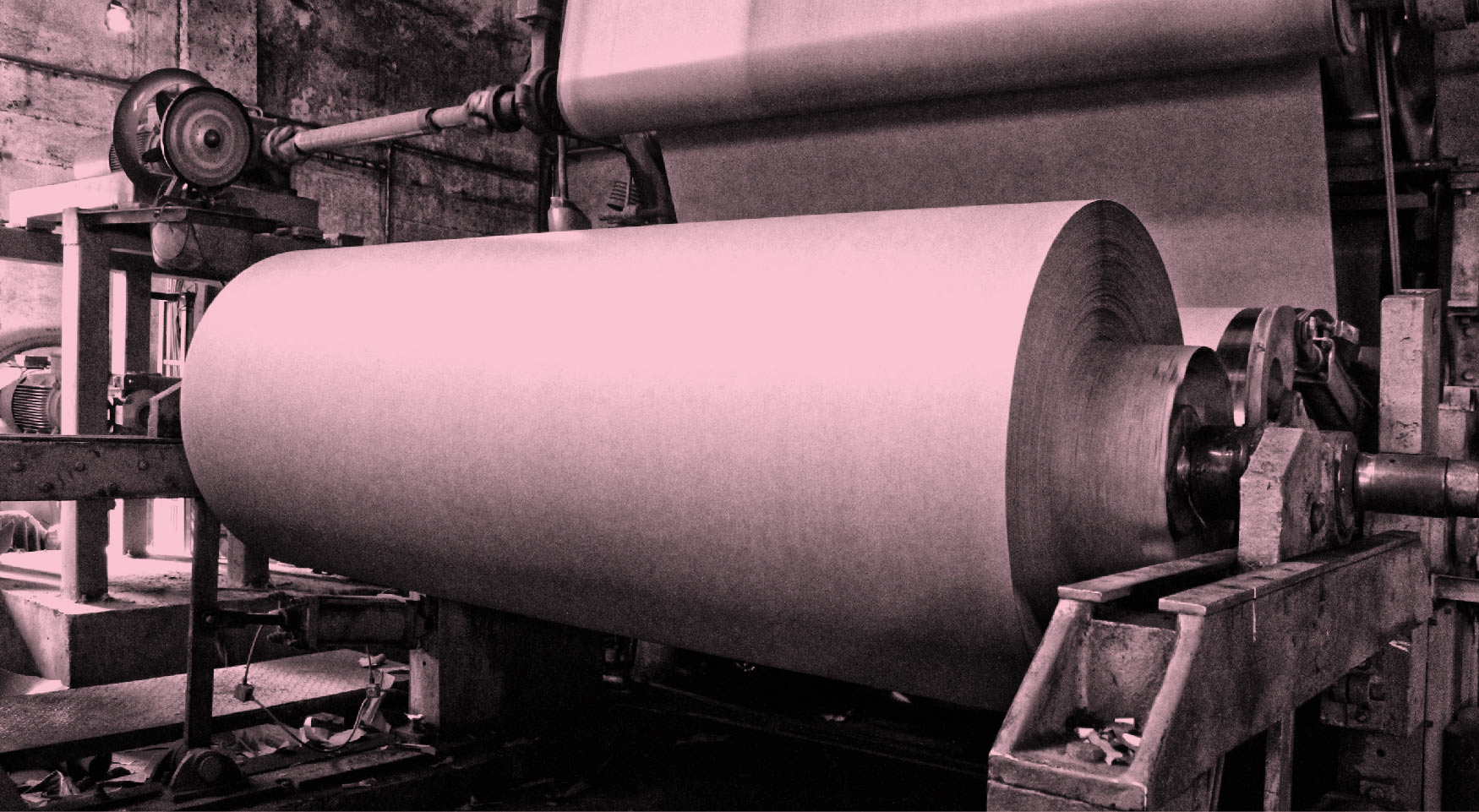

Paper Machine 1

paper machine deckle is 1.9 mts, speed 250 mpm& GSM range 100 - 450. It consist of open head box, single wire , couch press for better dryness at couch & nip press. PV hood & high velocity hood at MG.

-

Paper Machine 2

Paper machine deckle 2.2 mts, speed 400 mpm& GSM range 120 – 200 having pressurize head box, top & bottom wire for better cross width GSM. Long nip press, BDR, pocket ventilation & high velocity hood.

Thermo compressor system installed on both machines for removal of condensate and better efficiencies of steam.